A research team at Germany’s Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) has combined accelerated laboratory aging testing with outdoor exposure to improve the assessment of TOPCon solar module reliability.

The novel methodology is intended to provide data for validating and improving stress laboratory protocols. “By comparing the evolution of lab-induced damage under real outdoor conditions with known field degradation phenomena, it could validate that these individual lab tests effectively target field-relevant failure modes and accurately reflect their potential severity,” the scientists stressed.

In the paper “Combination of Indoor and Outdoor Measurements for the Identification of Degradation Trends in PV Modules,” published in RRL Solar, the researchers explained that one of the main goals of their work was to understand if outdoor conditions accelerate or decelerate specific degradation phenomena observed in indoor environments.

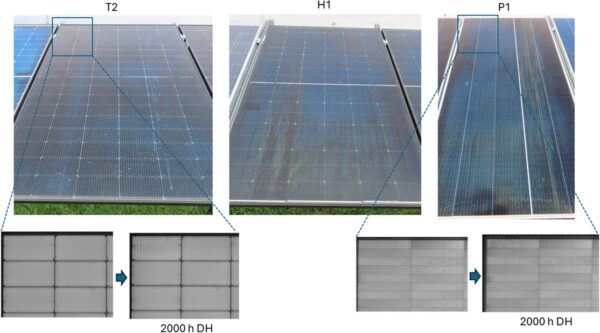

With the proposed approach, they tested six commercially available photovoltaic modules, of which three were based on TOPCon technology, two were designed with a heterojunction (HJT) architecture, and one was based on PERC cells. Their power output ranged from 391. W to 571.5 W. The names of the manufacturers were not disclosed.

The testing was performed for around eight months, with the IV curves being constantly monitored and kept at maximum power point (MPP). Indoor characterization measurements were taken for all modules before and after the accelerated aging.

Image: Fraunhofer ISE, RRL Solar, CC BY 4.0

The outdoor testing was conducted at Fraunhofer ISE’s monitoring station in Merdingen, southern Germany, with all modules being tilted at 30° with a south-facing orientation. “IV curve measurements are filtered at irradiance ranging between 775 and 825 W m−2, with irradiance and temperature fluctuations during curve acquisition kept below 1% for steady state conditions,” the research group specified.

The analysis showed that both TOPCon and HJT modules are prone to moisture ingress, with short-circuit current being affected, which is attributed by the scientists to be due to damage to the encapsulant layer or changes in the optical properties.

Furthermore, they revealed that the highest degradation rates were observed in a TOPCon module encapsulated with polyolefin elastomers (POE), namely 3% in the laboratory and 9.75% after 8 months of exposure at the testing field. “This suggests that even in the absence of acetic acid for POE, other factors, such as non-optimal lamination processing that releases curing residues or reactive species, polymer additives, or solder flux, could still contribute to moisture sensitivity and corrosion,” they further explained.

The outdoor testing also showed that the TOPCon modules are vulnerable to UV-induced degradation, although this was found to be in line with laboratory observations.

“The results suggest that standard IEC tests, while valuable, may not fully capture the complexity of field degradation,” the scientists concluded. “A combination of indoor and outdoor evaluations could further determine degradation risks, helping to improve the overall reliability of these advanced technologies and will be further developed.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.