As India scales up solar installations, manufacturers are re-evaluating not just cells and encapsulants but the frames as well. While aluminum has been the industry standard for decades, composite materials are now gaining traction due to their performance, cost advantages, and alignment with India’s domestic manufacturing push.

Aluminum remains popular for its strength and recyclability, but rising raw material costs, embedded carbon concerns, and logistics challenges have opened the door to alternatives. Composite frames, made from polyurethane or glass fiber-reinforced plastics, offer clear technical and economic benefits for India’s diverse and often harsh climate conditions.

What’s driving the shift?

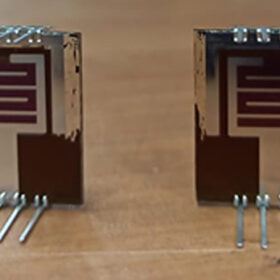

Frames contribute up to 10% of module costs and are critical for mechanical stability and long-term durability, particularly in environments like deserts, coastal zones, and high-humidity regions. Composite frames offer advantages over aluminum:

- Lower weight, reducing transport and installation costs

- Corrosion resistance, ideal for high-salinity and humid zones

- Lower thermal conductivity, which may mitigate PID (Potential-Induced Degradation)

- Reduced carbon footprint, especially when locally sourced

- Lower thermal expansion rates, minimizes the microcracks risks in solar cells especially in high temperature environments like India.

Global momentum

Composite frame adoption is expanding globally. Manufacturers are integrating polymer-based frames into mass production, optimizing for rooftop and bifacial modules, and creating hybrid frames for challenging climates. The goal is consistent: reduce total cost of ownership without compromising durability.

India’s window of opportunity

With India’s Production Linked Incentive (PLI) scheme and the Atmanirbhar Bharat initiative, composite frames align well with the country’s goals for manufacturing localization and strategic material independence. Aluminum profiles, especially anodized ones, are often imported. Composites present an opportunity to build a more self-reliant supply chain.

Still, adoption in India has been slow. A key barrier is the absence of standard testing protocols suited to India’s varied climate. While IEC certifications provide a base, field validation in Indian conditions is critical.

What’s needed

For composite frames to scale, four things must align:

- Indian-specific testing standards to build confidence in long-term performance

- Local manufacturing to improve cost efficiency and reduce dependence on imports

- Policy support, such as incentives or green procurement mandates

- Pilot projects led by material suppliers, module makers, and EPC firms to demonstrate reliability

Looking ahead

As India targets 500 GW of non-fossil capacity by 2030, small component-level innovations can drive big system-level gains. The module frame may seem minor, but it can make a measurable difference in cost, reliability, and sustainability.

Whether composites fully replace aluminum or coexist with it, their rise marks a shift in how we think about solar hardware, moving from static choices to strategic ones focused on total lifecycle value.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.